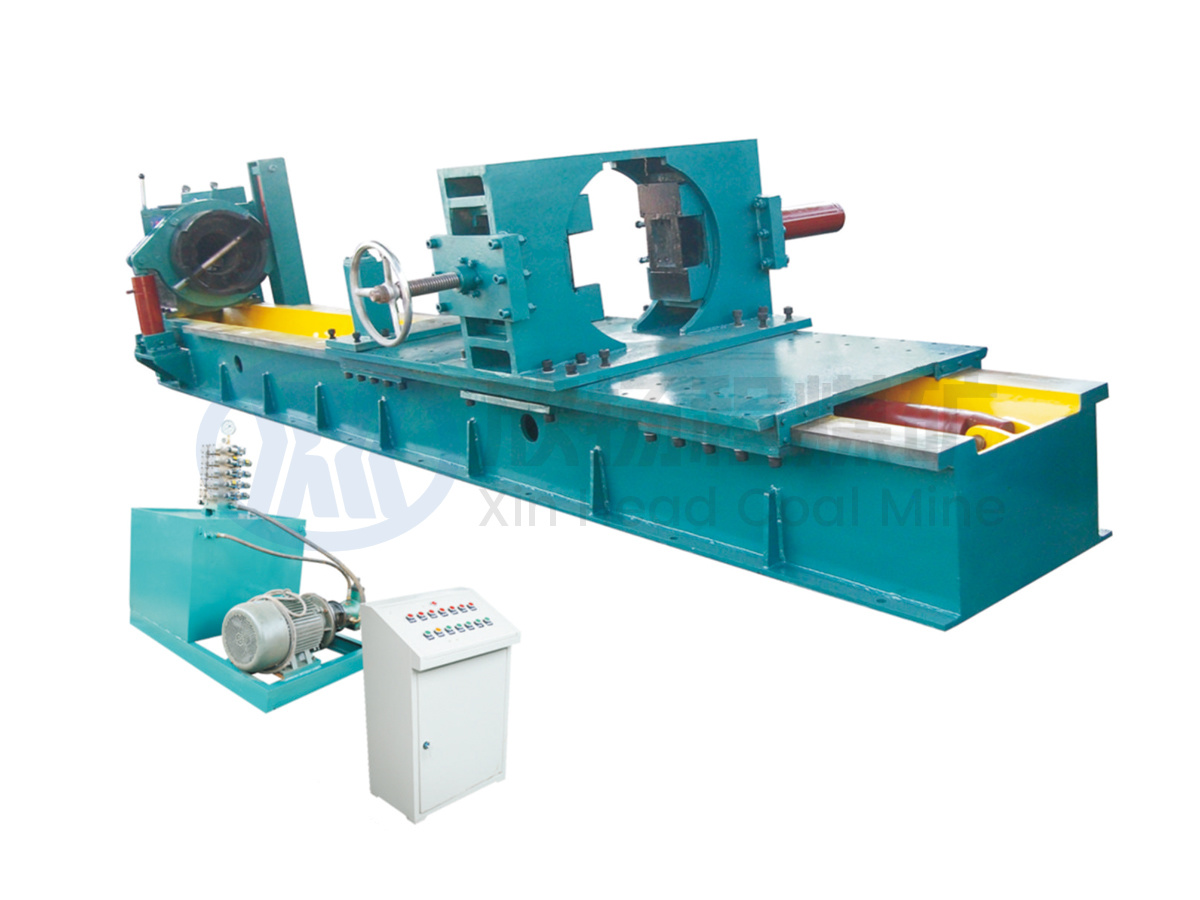

U-shaped steel bracket roll forming repair machine

Key words:

Coal mine equipment

hiddenValue

Product Introduction

The GCF-2 and GCF-3 U-shaped steel bracket forming and repairing machines jointly developed by our company and the Mechanical College of Henan University of Technology are based on the GCF-1 type, after extensive consultation with users' opinions and suggestions, repeated tests, tackling key problems and development. It integrates the rolling forming and repairing of U-shaped steel brackets, and is suitable for the production and repair of arched bracket beams, legs, three-heart arch beams and legs. It has reasonable design and reliable action, the advantages of simple operation, high precision and high degree of automation have filled the domestic blank.

The product is a patented product. Patent number: ZL 200820069216.3 in the field of U-shaped steel bracket production, is the only country through the practice test, in line with the national standard of retractable bracket, and has been mature for many years of new patent products.

Molding:

At present, most of the coal mines in our country use U-shaped steel to make arch brackets according to the principle of molding, using a press machine with a special mold to press them. Because the molding cannot be completed at one time, many skirts are caused, which makes the stress of U-shaped steel uneven and directly affects the working strength of U-shaped steel. Moreover, this molding method has low processing efficiency and low manufacturing precision (arch brackets made by this method, the radius of curvature and chord length of each place are completely based on the operation experience and skills of the workers, so the error is relatively large); a series of shortcomings such as high labor intensity and poor safety of the workers, the use of roll forming to make arch brackets, completely overcome the use of the principle of molding A series of shortcomings produced, with the following advantages:

(1) High production efficiency;

(2) The production precision is high, and the radius of curvature can be adjusted arbitrarily and conveniently;

(3) The labor intensity of workers is greatly reduced and the operation is safe.

(4) It will not produce the skirt caused by multiple molding, reduce the pressure defect of the arch bracket, and can effectively reduce the damage probability of the U-shaped steel shed.

This kind of equipment adopts the advanced domestic technology "side roller swing type four-roller roll bending principle" to realize the U-shaped steel bracket beam leg roll forming in the fixed-length blanking, one-time feeding, automatic forming. Suitable for 25U, 29U, 36U, 40U four kinds of U-shaped steel beam and leg production molding. The technical indicators of the formed U-shaped steel bracket meet all the requirements in the MT195-89 standard of "Manufacturing Technology of U-shaped Steel Retractable Bracket for Coal Mine.

Fix:

After the used U-shaped steel bracket is recycled to the ground, most coal mines are abandoned, or idle and piled up, or when scrap iron is treated, very few coal mines have partially repaired and reused it. The method adopted is still to repair it by using the molding principle, which has a series of shortcomings such as low repair efficiency, large strength loss to U-shaped steel, low repair accuracy, skirt and the like.

The rolling forming repair machine can repair and reuse most of the waste U-shaped steel arch brackets after correction, and overcome a series of shortcomings existing in the molding repair. It has the advantages of high repair efficiency, small strength loss of U-shaped steel, high repair accuracy, and no skirt after forming.

Main technical parameters of GCF-2

1. Scope of application: 25U, 29U, 36U

2. Curvature radius of U-shaped steel after forming ≥ 1100mm

3. The length of straight sections at both ends of the formed U-shaped steel beam is ≤ 80mm

4. The equipment does not have the function of straightening, and the radius of curvature can only be changed from large to small when bending.

5. Production efficiency: 30 rolling beams/hour and 60 rolling legs/hour

6. Rolling speed: 0-4.3 m/min

7. Main pump station: rated power 30KW, flow 120L/min, maximum working pressure 16Mpa

Auxiliary pumping station: rated power 18.5KW flow 48L/min maximum working pressure 20Mpa

Lubrication pump station: rated power 0.55KW flow 3.7L/min maximum working pressure 2Mpa

8. Overall dimensions of the host: 2800 × 2800 × 1760(mm)

Overall dimension of pump station: 3200 × 1400 × 1900(mm) including oil tank

Wherein the fuel tank: 1500 × 1100 × 1200(mm)

9. Applicable environmental conditions: temperature 0-40 ℃, oil temperature <65 ℃, altitude 1000 meters

Main technical parameters of GCF-3

1. Scope of application: 25U, 29U, 36U, 40U

2. Curvature radius of U-shaped steel after forming ≥ 1100mm

3. The length of straight sections at both ends of the formed U-shaped steel beam is ≤ 80mm

4. The equipment does not have the function of straightening, and the radius of curvature can only be changed from large to small when bending.

5. Production efficiency: 30 rolling beams/hour and 60 rolling legs/hour

6. Rolling speed: 0-4.3 m/min

7. Main pump station: rated power 45KW, flow 142L/min, maximum working pressure 16Mpa

Auxiliary pumping station: rated power 18.5KW flow 48L/min maximum working pressure 20Mpa

Lubrication pump station: rated power 0.55KW flow 3.7Llmin maximum working pressure 2Mpa

8. Overall dimensions of the host: 2800 × 2800 × 1760(mm)

Overall dimension of pump station: 3500 × 1400 × 1900(mm) including oil tank

Wherein the fuel tank: 1800 × 1200 × 1200(mm)

9. Applicable environmental conditions: temperature 0-40 ℃, oil temperature <65 ℃, altitude 1000 meters

Related Products

Leave your contact information to get a free product quote

Hello, what can we do for you?

Xinyang Cheng Coal Mine Equipment

Production of coal mine special equipment, maintenance of fully mechanized hydraulic support and other coal mine equipment

Strong technical force, advanced detection means, production and maintenance equipment

Contact Us

Address: Boai Industrial Cluster (South Section of Xingyuan Road)

Mobile end